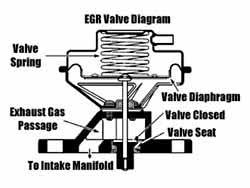

The EGR valve has a control hose that goes to the intake plenum and allows the EGR valve to open at wide-open-throttle, allowing some exhaust gas to mix with the intake stream. The exhaust gas conections to the EGR valve are 3 metal tubes. One goes to the driver exhaust manifold and the others to the bottom of intake plenum on each side (red dots in 2.).

To test the EGR valve operation, start the engine and then disconnect the control hose (light blue dot in 2.). The EGR valve should open and engine should slow or hesitate. If disconnecting the hose makes no difference, either the hose is leaky/ blocked or the EGR exhaust gas pipes are blocked.

The basic failure of an EGR valve is the diaphram that senses intake maifold vacuum and opens/closes the valve. With a clean hose on the control input, suck on the hose and put your tongue against the open end of the hose. It should hold the lower pressure, stick to your tongue, for at least a minute. You can do the same test with a vacuum gauge of course, if you have one. If the valve won't hold low pressure, then it won't close completely at idle and your engine will idle poorly.

Supposedly replacement can be accomplished with the engine in the car. We did Shahram's while his engine was out of the chassis getting the turbos replaced. It was still difficult this way.

Procedure:

1. Spray everything around the EGR valve with a penetrating lubricant, also the fitting on the drivers side exhaust manifold. I recommend Blaster brand.

2. Disconnect the vacuum line from top of the EGR valve (light blue dot in 2.).

3. Remove the water line fom the driver side of the valve's location (yellow dots in 2.) (3 x 10mm). Get a bucket before cracking the line, just about every bit of water left in the heads will come out of this tube. Remove the 3 rubber hoses from the metal water feed tube up top (3 x hoseclamps).

4. Remove the bolts on the EGR valve (6 green dots in 2.) (6 x 12mm).

5. Remove the fitting on the exhaust manifold (1 x 23mm?), Not sure on the size, I just used a crescent wrench to remove it.

6. Follow the exhaust tube from the EGR valve to the underside driver side of the intake plenum. Disconnect it there (2 x 10mm). Remove the bolt holding the line to a bracket on the rear side of the head (1 x 10mm) to loosen the feed line. Pull the line upwards from the EGR valve & rotate/slide the valve out of it's mounting position (3.).

7. Note the orientation of the exhaust feed tube on the EGR valve. Remove the exhaust feed tube from the valve (purple dot in 2.). Put anti-seize compound on both ends of the fittings. Install tube on new EGR valve. Torque to 25-33 ft-lbs.

8. Clean off all old gasket material on all seating surfaces.

9. Rotate/side the new EGR valve into position. Start the threads on the exhaust manifold fitting. Bolt the EGR valve back to the engine (2 x 12mm). Use anti-seize compound on the bolts. Torque to 15-20 ft-lbs.

10. Start the threads on the driver side exhaust feed tube in all locations (3 x 10mm, 2 x 12mm). Use anti-seize compound on all. Use appropriate replacement gaskets. After all are started, torque plenum bolts to 6.2-8.0 ft-lbs, EVG valve bolts to 15-20 ft-lb, torque bracket bolt to 8-10 ft-lbs.

11. Reconnect the passenger side exhaust feed tube (2 x 12mm) with gasket. Use anti-seize compound on the bolts. Torque to 15-20 ft-lbs.

12. Torque exhaust manifold fitting to 25-33 ft-lbs.

13. Reconnect vacuum line to top of EGR valve (1 x hoseclamp).

14. Install the water feed tube on driver side of EGR with new gasket (2 x 10mm, 3 x hoseclamp). Torque to 10-15 ft-lbs.

Originally published 11-25-99.

© Twin Turbo Zs of Dallas - All Rights Reserved 2000

2.

3.